Main content

Top content

Workshops and facilities

The well-equipped textile workshops at Osnabrück University enable creative, technical/design and experimental work to be carried out in an academic context, either individually, collaboratively or as part of a project. The workshops and laboratories in the areas of weaving, knitting, sewing, embroidery, tufting, printing and pattern design (PC pool) are equipped for handicraft and computerized work. As a result, students can learn not only handicraft, but also industrial, analogue and digital processes.

Here you will find illustrated descriptions of the following devices used at Textile Studies at Osnabrück University: a digital jacquard loom TC2, a punchcard jacquard loom, a digital pattern loom with 24 shafts, a countermarch loom with 8 shafts, several computerized sewing machines, an embroidery machine, a tufting system, a transfer press, a screen printing system and several knitting machines. The Textile Studies department also has a professional ozone cabinet, a large format laser cutter, a button machine, cutting table, table looms from 4 to 8 shafts, weaving frames, more digital and analogue embroidery machines, a felting machine and ironing stations. An illustrated description of this equipment will follow as soon as possible.

TC2 digital Jacquard loom

Weaving width 73 cm

Digital control, preparation of the weaving cartridge from the hand-drawn design and processing in Photoshop to the finished weaving design.

Used for teaching, for collaborative projects and student designs, e.g. for the creation of a collection of wool blankets for the Tuchmacher Museum Bramsche in the Bauhaus project, the prototype of the academic scarf for doctoral candidates at Osnabrück University, and the creation of a collection for the historic Beiderwand Weaving Workshop run by Stiftung Mensch in Meldorf.

Punchcard Jacquard loom

From analogue to digital:

The fully functional punchcard Jacquard loom at Osnabrück University’s Department of Textile Studies is an impressive demonstration of the transformation from analogue to digital technology in textiles.

Der Lochkartenjacquardwebstuhl in Osnabrück ist ausgestattet mit einer 400er Chemnitzer Grobstich Jacquardmaschine.

The punchcard Jacquard loom in Osnabrück is equipped with a 400 Chemnitz coarse stitch Jacquard machine. It also comes with a card punching machine, a card sewing board and a Jacquard teaching model. Textile Studies students are able to experience the entire work procedure – from making the design, drawing the cartridge, and punching and sewing the card, to hooking the punchcard into the Jacquard machine and weaving on the Jacquard loom. The loom is used for teaching, e.g. in preparation for the textiles excursion to Sri Lanka or in the course entitled “From Analogue to Digital.”

Digital pattern loom

Patronic designer loom

The Patronic loom is a digital pattern loom with 24 shafts. The fabric cartridge is created in a digital weaving program such as DB Weave, Weave Point or Pointcarré, retrieved on the loom and implemented by hand as a fabric. The pattern loom enables students to experiment flexibly with a wide variety of fabric weaves, and creates a bridge from the analogue technology on the countermarch loom to digital implementation.

Countermarch loom

Eight shafts / eight treadles:

The countermarch loom at the Department of Textile Studies has a weaving width of 80 centimeters, eight shafts and eight treadles. It is used in teaching to experiment with weaves, materials and the implementation of fabric designs, e.g. in the course on “Patterns and Material” or the development of a collection for the Women Weave Project with Tamil war widows in the north of Sri Lanka.

Computerized sewing machines

Janome Model DC3018

Modern computerized sewing machines from Janome, model DC3018, with functional LC display, built-in threader, offer 18 sewing programs as well as functions such as 3-step buttonholes, which enable the implementation of various sewing jobs. These machines are used in various practice-oriented seminars.

Embroidery machine

Brother PR 600

The BROTHER PR 600 semi-professional embroidery machine can be used to embroider multi-colored patterns, graphics and lettering on textiles. The machine is operated via an integrated display and, in addition to pre-stored fonts and motifs, also allows you to implement your own ideas.

Tufting system

The professional tufting system offers the possibility of producing three-dimensional textile surfaces. Compressed air is used to insert the yarn into the stretched fabric using the tufting gun. The system can be used by students in seminars to implement their own designs.

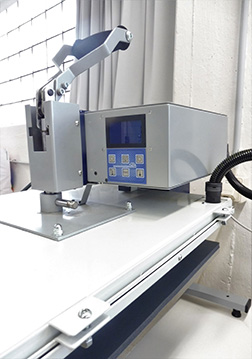

Transfer press

Thermopress SwingerPlus mit MiTEC-Heiztechnologie

The Thermopress SwingerPlus with MiTEC heating technology is a digital and universal professional device. With Teflon-coated heating elements, it can be used for a wide variety of transfer tasks. The transfer press was developed for professional classic and sublimation transfer applications. It is a mechanical swivel press with electronically controlled heating elements. It is particularly suitable for printing on textiles and can be used in various seminars.

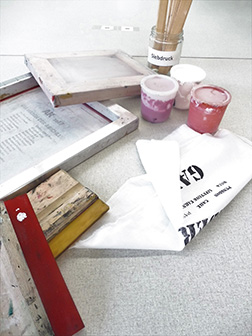

Screen printing

Screen printing is a printing process in which liquid ink is printed through a fine mesh fabric onto the material to be printed using a rubber squeegee. This mesh can be provided with individual stencils to print patterns, motifs and graphics. This technique is very suitable for textiles and is used in a variety of contexts.

Knitting machines

Brother's manual knitting machines in various designs enable the realization of different knitting projects. Simple and complex knitting patterns can be implemented on the single and double needle bed. All machines have an automatic punch card system, which can be used to knit additional patterns. All machines can be used in the practical seminars.